produkt introduktion

Vår fiber laser skärmaskin samlokaliseras med den avancerade lasergeneratorn som avger laserstråle med hög energitäthet. Laserstrålen fokuseras på arbetsstyckets yta som en ultrafin fokusfakula och orsakar att det bestrålade området omedelbart smälter och förångas. Styr laserskäraren automatiskt för att uppnå skäruppdraget. Laserutrustningen består av avancerad laserteknik, CNC-teknik och mekanisk teknik. Det är tillämpligt för bearbetning av metallplåt som rostfritt stål, kolstål, koppar, aluminium och metallrör. Det har använts i stor utsträckning vid plåtbearbetning, maskintillverkning och precisionsbearbetning, etc.

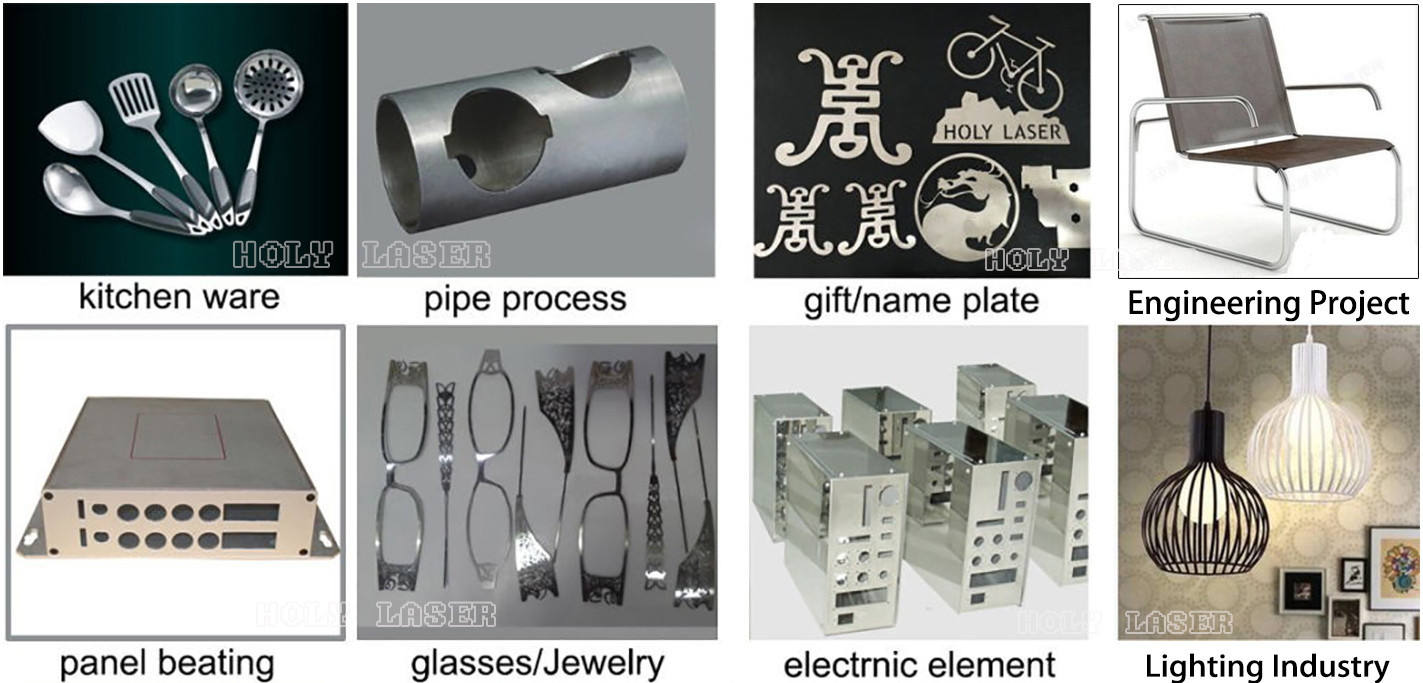

Tillämpade industrier

Vår metall laserskärningsmaskin tillämpas inom plåtbearbetning, flyg, rymdfärder, elektronik, elektriska apparater, tunnelbanedelar, bilar, maskiner, precisionskomponenter, fartyg, metallurgisk utrustning, hiss, hushållsapparater, presenter och hantverk, verktygsbearbetning, utsmyckning, reklam, metallförädling av olika tillverkningsindustrin.

Tillämpade material

Vår laserskärmaskin används huvudsakligen för skärning av kolstål, kiselstål, rostfritt stål, aluminiumlegering, titanlegering, galvaniserad stålplåt, betbräda, aluminiumzinkplåt, koppar och många typer av skärning av metallmaterial och så vidare.

Fördelarna med Fiberlaserskärmaskin

1) Utmärkt strålekvalitet: Mindre fokusdiameter och hög arbetseffektivitet, hög kvalitet.

2) Hög skärhastighet: Skärhastigheten är mer än 45 m / min

3) Stabil drift: Antagande av världens största importfiberlasrar, stabil prestanda, nyckeldelar kan nå 100 000 timmar

4) Hög effektivitet för fotoelektrisk omvandling: Jämför med CO2-laserskärningsmaskin, fiberlaserskärningsmaskin har tre gånger fotoelektrisk omvandlingseffektivitet

5) Låg kostnad och lågt underhåll: Spara energi och skydda miljön. Fotoelektrisk omvandlingsfrekvens är upp till 25-30%. Låg elförbrukning, det är bara cirka 20% -30% av traditionell CO2 laserskärmaskin. Fiberlinjeöverföring behöver ingen reflekterande lins, spara underhållskostnader

6) Enkla operationer: fiberlinjeöverföring, ingen justering av optisk väg

7) Superflexibla optiska effekter: Kompakt design, enkla till flexibla tillverkningskrav

8) Dubbel enhet: annorlunda den traditionella enhetsmaskinen, den dubbla drivenheten är mer stor, hastigheten är snabbare och hög procession

Teknisk parameter

| Modell nr | ACCURL 500W-3015 |

| Laserkraft | 500W |

| Laservåglängd | 1080mm |

| lasing midium | YVO4 |

| min linje bredd | <0,15 mm |

| kör | dubbel enhet |

| max körhastighet | 60m / min |

| max arbetsområde | 3000 * 1500 mm |

Z-axel | 120mm |

| skärstjocklek av kolstål | 6mm |

| Spänning | 380V / 50HZ |

| Kylväg | Vattenkylning |

| Platsprecision | ≤ ± 0,05 mm |

| Stödformat | PLT, DXF, BMP, AI |

| Arbetsbord max. ladda | 1000 kg |

| Överföringsmetod | Kulskruvöverföring |

| Tabelldrivet system | Japanska importerade Panasonic servomotor & körsystem |

| Fokusmetod | Följande och automatiskt justera fokus |

| Kontroll metod | Offline rörelsekontroll |

| Kontrollprogramvara | Cypcut Laser Cutting Software |