Produktbeskrivning

Laserskärmaskin i fibermetall

1. Låg kostnad och strömförbrukningen är 0,5-1,5kw/h; Kunden kan skära alla typer av metallplåtar genom att blåsa luft;

2. Högpresterande. Importerade den originalförpackade fiberlasern, med stabil prestanda och livslängden är över 100 000 timmar;

3. Hög hastighet och effektivitet, hastigheten för att skära metallplåt nära tiotals meter;

4. Lasern underhållsfri;

5. Skärkanten ser perfekt ut och utseendet är slätt och vackert;

6. Importerad transmissionsmekanism och servomotor, och hög skärnoggrannhet;

7. Dedikerad programvara gör att grafik eller text omedelbart kan utformas eller bearbetas. Flexibel och enkel manövrering.

Parameter av Laserskärmaskin i fibermetall

| Laserkraft | 500W | |

| Laserkälla | Raycus eller IPG Laser Fiber Laser Source | |

| Lasertyp | Importerad Fiber Laser eller Top Brand China Fiber Laser | |

| Laserteknik | Tysklands teknik | |

| XYZ Arbetsområde | 2500*1300 | 3000*1500 |

| Max. Skärtjocklek (CS) | 1 mm - 5 mm | |

| Max. Skärhastighet | 5-15 meter/min (upp till material) | |

| Max. Platshastighet | 60m / min | |

| Laservåglängd | 1070nm | |

| Minsta radbredd | ≤0.1mm | |

| Platsprecision | ≤ ± 0,05 mm | |

| Omplaceringsprecision | ± 0,02 mm | |

| Max. rörelsehastighet | 100m / min | |

| Stödformat | PLT, DXF, BMP, AI | |

| Strömbehov | 380V / 50Hz | |

| Kylväg | Vattenkylning | |

| Arbetsbord max. ladda | 1000 kg | |

| Överföringsmetod | Kulskruvöverföring | |

| Tabelldrivet system | Japansk importerad servomotor och körsystem | |

| Fokusmetod | Följande och automatiskt justera fokus | |

| Kontroll metod | Offline rörelsekontroll | |

| Kontrollprogramvara | Perfekt Laser Professional-programvara för skärning av laser | |

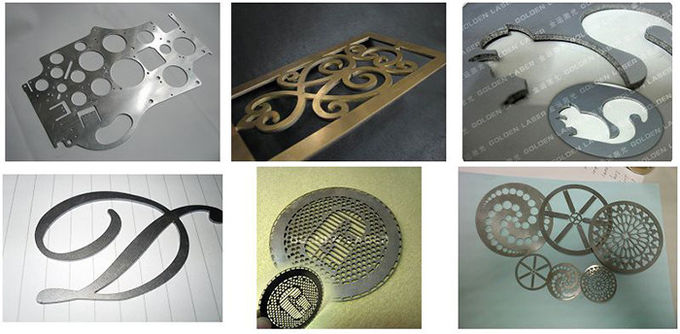

Applikation och prov

Tillämpas inom plåtbearbetning, flyg, rymdfärd, elektronik, elektriska apparater, tunnelbanedelar, bilar

maskiner, precisionskomponenter, fartyg, metallurgisk utrustning, hiss, hushållsapparater, gåvor och hantverk,

verktyg bearbetning, utsmyckning, reklam, metall utländska bearbetning olika ma

Alternativ för laserkälla

Raycus: 500W, 750W, 1000W, 1500W,2200W,3300W,4400W

IPG: 500W, 700W, 1000W, 1500W, 2000W, 3000W, 4000W,

Olika laserkrafter på grund av olika laserskärningstjocklek, material och produktionskvantitet.

Installation

Efter att maskinen når köparens plats är ingenjörerna från säljaren ansvariga för maskininstallationen

och driftsättning genom att använda specialverktygen med hjälp av köparen. Köparen bör betala för vår ingenjör

visumavgift, flygbiljetter, boende, måltider mm.

Den gemensamma kunskapen om skydd för lasersäkerhet

Den grundläggande principen för lasermodul och strukturen för laserskärningsmaskin

Funktionerna hos fiberlaserskärmaskin

Utrustning och ansökan om ansökan

Färdigheter för dagligt underhåll av utrustning, justering av lasermodul och utbyte av reservdelar.

Installation och träningstid är cirka 5 till 7 dagar.

Garanti och service

1). 1 års garanti för hela maskinen

2). 2 års garanti för fiberlaserkällan

3). Livslångt underhåll

4). Under garantiperioden, om det går sönder eller några delar skadas (förutom de mänskliga faktorerna och faktorerna

av force majeure), säljaren bör ansvara för reparation gratis, delarna måste bytas ut kommer att vara

tillhandahålls från säljaren gratis (förutom snabbslitagedelen).

5). Efter att garantitiden löpt ut behöver köparen bara betala den faktiska underhållskostnaden.

6). Vissa kunder kommer att göra ett återbesök flera gånger ett år, och kommer att tillhandahålla teknisk support

service när som helst, och tillhandahåll även reservdelar när som helst köparen vill.

7). Svarstid efter försäljningsservice: snabbt svar inom 8 arbetstimmar, efter att ha fått reparationsanropet,

vår eftermarknadsingenjör kommer att svara så snart som möjligt.